Spray Flags and Inputs

In the

GNUmakefile, specifyUSE_PARTICLES = TRUEandSPRAY_FUEL_NUM = NwhereNis the number of liquid species being used in the simulation.Depending on the gas phase solver, spray solving functionality can be turned on in the input file using

pelec.do_spray_particles = 1orpeleLM.do_spray_particles = 1.The units for PeleLM and PeleLMeX are MKS while the units for PeleC are CGS. This is the same for the spray inputs. E.g. when running a spray simulation coupled with PeleC, the units for

particles.fuel_cpmust be in erg/g.There are many required

particles.flags in the input file. For demonstration purposes, 2 liquid species ofNC7H16andNC10H22will be used.The liquid fuel species names are specified using

particles.fuel_species = NC7H16 NC10H22. The number of fuel species listed must matchSPRAY_FUEL_NUM.Many values must be specified on a per-species basis. Following the current example, one would have to specify

particles.NC7H16_crit_temp = 540.andparticles.NC10H22_crit_temp = 617.to set a critical temperature of 540 K forNC7H16and 617 K forNC10H22.Although this is not required or typical, if the evaporated mass should contribute to a different gas phase species than what is modeled in the liquid phase, use

particles.dep_fuel_species. For example, if we wanted the evaporated mass from both liquid species to contribute to a different species calledSP3, we would putparticles.dep_fuel_species = SP3 SP3. All species specified must be present in the chemistry transport and thermodynamic data.

The following table lists other inputs related to

particles., whereSPwill refer to a fuel species name

Input |

Description |

Required |

Default Value |

|---|---|---|---|

|

Names of liquid species |

Yes |

None |

|

Name of gas phase species to contribute |

Yes |

Inputs to

|

|

Liquid reference temperature |

Yes |

None |

|

Critical temperature |

Yes |

None |

|

Boiling temperature at atmospheric pressure |

Yes |

None |

|

Liquid \(c_p\) at reference temperature |

Yes |

None |

|

Latent heat at reference temperature |

Yes |

None |

|

Liquid density |

Yes |

None |

|

Liquid thermal conductivity (currently unused) |

No |

|

|

Liquid dynamic viscosity (currently unused) |

No |

|

|

Couple momentum with gas phase |

No |

|

|

Evaporate mass and exchange heat with gas phase |

No |

|

|

Fix particles in space |

No |

|

|

\(N_{d}\); Number of droplets per parcel |

No |

|

|

Output ascii files of spray data |

No |

|

|

Particle CFL number for limiting time step |

No |

|

|

Ascii file name to initialize droplets |

No |

Empty |

If an Antoine fit for saturation pressure is used, it must be specified for individual species,

particles.SP_psat = 4.07857 1501.268 -78.67 1.E5

where the numbers represent \(a\), \(b\), \(c\), and \(d\), respectively in:

\[p_{\rm{sat}}(T) = d 10^{a - b / (T + c)}\]If no fit is provided, the saturation pressure is estimated using the Clasius-Clapeyron relation; see

Temperature based fits for liquid density, thermal conductivity, and dynamic viscosity can be used; these can be specified as

particles.SP_rho = 10.42 -5.222 1.152E-2 4.123E-7 particles.SP_lambda = 7.243 1.223 4.223E-8 8.224E-9 particles.SP_mu = 7.243 1.223 4.223E-8 8.224E-9

where the numbers respresent \(a\), \(b\), \(c\), and \(d\), respectively in:

\[ \begin{align}\begin{aligned}\rho_L \,, \lambda_L = a + b T + c T^2 + d T^3\\\mu_L = a + b / T + c / T^2 + d / T^3\end{aligned}\end{align} \]If only a single value is provided, \(a\) is assigned to that value and the other coefficients are set to zero, effectively using a constant value for the parameters.

Spray Injection

Templates to facilitate and simplify spray injection are available in PeleMP. To use them, changes must be made to the input and SprayParticlesInitInsert.cpp files. Inputs related to injection use the spray. parser name. To create a jet in the domain, modify the InitSprayParticles() function in SprayParticleInitInsert.cpp. Here is an example:

void

SprayParticleContainer::InitSprayParticles(

const bool init_parts, ProbParm const& prob_parm)

{

amrex::ignore_unused(prob_parm);

int num_jets = 1;

m_sprayJets.resize(num_jets);

std::string jet_name = "jet1";

m_sprayJets[0] = std::make_unique<SprayJet>(jet_name, Geom(0));

return;

}

This creates a single jet that is named jet1. This name will be used in the input file to reference this particular jet. For example, to set the location of the jet center for jet1, the following should be included in the input file,

spray.jet1.jet_cent = 0. 0. 0.

No two jets may have the same name. If an injector is constructed using only a name and geometry, the injection parameters are read from the input file. Here is a list of injection related inputs:

Input |

Description |

Required |

|---|---|---|

|

Jet center location |

Yes |

|

Jet normal direction |

Yes |

|

Jet velocity magnitude |

Yes |

|

Jet diameter |

Yes |

|

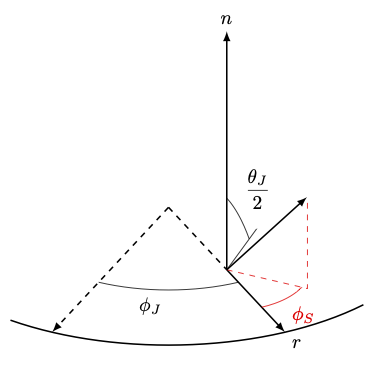

\(\theta_J\); Full spread angle in degrees from the jet normal direction; droplets vary from \([-\theta_J/2,\theta_J/2]\) |

Yes |

|

Temperature of the injected liquid |

Yes |

|

Mass fractions of the injected

liquid based on

|

Yes, if

|

|

\(\dot{m}_{\rm{inj}}\); Mass flow rate of the jet |

Yes |

|

Sets hollow cone injection with angle \(\theta_J/2\) |

No (Default: 0) |

|

\(\theta_h\); Adds spread to hollow cone \(\theta_J/2\pm \theta_h\) |

No (Default: 0) |

|

\(\phi_S\); Adds a swirling component along azimuthal direction |

No (Default: 0) |

|

Beginning and end time for jet |

No |

|

Droplet diameter distribution

type: |

Yes |

Demonstration of injection angles. \(\phi_J\) varies uniformly from \([0, 2 \pi]\)

Care must be taken to ensure the amount of mass injected during a time step matches the desired mass flow rate. For smaller time steps, the risk of over-injecting mass increases. To mitigate this issue, each jet accounts for three values: \(N_{P,\min}\), \(m_{\rm{acc}}\), and \(t_{\rm{acc}}\) (labeled in the code as m_minParcel, m_sumInjMass, and m_sumInjTime, respectively). \(N_{P,\min}\) is the minimum number of parcels that must be injected over the course of an injection event; this must be greater than or equal to one. \(m_{\rm{acc}}\) is the amount of uninjected mass accumulated over the time period \(t_{\rm{acc}}\). The injection routine steps are as follows:

The injected mass for the current time step is computed using the desired mass flow rate, \(\dot{m}_{\rm{inj}}\) and the current time step

\[m_{\rm{inj}} = \dot{m}_{\rm{inj}} \Delta t + m_{\rm{acc}}\]The time period for the current injection event is computed using

\[t_{\rm{inj}} = \Delta t + t_{\rm{acc}}\]Using the average mass of an injected parcel, \(N_{d} m_{d,\rm{avg}}\), the estimated number of injected parcels is computed

\[N_{P, \rm{inj}} = m_{\rm{inj}} / (N_{d} m_{d, \rm{avg}})\]

If \(N_{P, \rm{inj}} < N_{P, \min}\), the mass and time is accumulated as \(m_{\rm{acc}} = m_{\rm{inj}}\) and \(t_{\rm{acc}} = t_{\rm{inj}}\) and no injection occurs this time step.

Otherwise, \(m_{\rm{inj}}\) mass is injected and convected over time \(t_{\rm{inj}}\) and \(m_{\rm{acc}}\) and \(t_{\rm{acc}}\) are reset.

If injection occurs, the amount of mass injected, \(m_{\rm{actual}}\), is summed and compared with the desired mass flow rate. If \(m_{\rm{actual}} / t_{\rm{inj}} - \dot{m}_{\rm{inj}} > 0.05 \dot{m}_{\rm{inj}}\), then \(N_{P,\min}\) is increased by one to reduce the liklihood of over-injecting in the future. A balance is necessary: the higher the minimum number of parcels, the less likely to over-inject mass but the number of time steps between injections can potentially grow as well.